Rattling Noises in Your Heating System: Causes & Solutions

Installing a furnace the right way matters — for safety, for comfort, and for your energy bills. A correct install keeps your system running efficiently, helps it last longer, and prevents costly issues down the road. Below you’ll find a straightforward walkthrough of the installation process, typical costs, permit requirements, and how to pick the right unit. We’ll also cover testing and maintenance so your new furnace performs reliably from day one. Taking the time to understand these key factors empowers homeowners to make informed decisions and ensures peace of mind throughout the process.

What Are the Essential Steps for Proper Furnace Installation?

A reliable furnace install follows a clear sequence: evaluate the space, size the unit correctly, follow the manufacturer’s setup instructions, and meet local code requirements. Skipping any step can reduce performance or create safety risks, so each part of the process matters. Additionally, proper ductwork inspection and sealing are critical to maximize efficiency and indoor air quality. Ensuring that the installation site is clean and accessible also helps prevent delays and complications during the project.

How Do Licensed HVAC Technicians Ensure Safe and Efficient Installation?

Licensed HVAC technicians bring training and on-the-job experience to every install. They know how to size the system, set up venting, connect gas and electrical safely, and follow local building codes. That expertise reduces the chance of leaks, poor airflow, or other problems that can affect comfort and safety. Their knowledge also extends to troubleshooting unexpected issues on site, ensuring that the installation is customized to your home’s unique needs.

Strong project planning and on-site oversight help make sure each installation meets safety and quality standards. Technicians also provide valuable guidance on system operation and maintenance, helping homeowners get the most from their investment.

HVAC Installation Project Management: Planning, Safety & Quality

Project management focuses on planning, scheduling, budgeting, and coordinating materials and permits so the project stays on track. Site management handles the day-to-day work: supervising crews, enforcing safety rules, and keeping quality control front and center. HVAC Project Management and Site Supervision, V Vakiloroaya, 2026. Effective communication between all parties involved ensures that timelines are met and any challenges are addressed promptly, minimizing disruptions and cost overruns.

What Tools and Safety Procedures Are Required During Installation?

Technicians rely on basic hand tools (wrenches, screwdrivers), diagnostic tools (multimeters, manometers), and safety gear. Proper ventilation, gas‑line checks, electrical isolation, and following manufacturer safety steps are all essential. These precautions keep both the crew and your home safe during the work. Additionally, the use of personal protective equipment (PPE) such as gloves, goggles, and respirators is standard practice to prevent injuries and exposure to hazardous materials.

How Much Does Furnace Installation Cost and What Factors Affect Pricing?

Installation costs vary depending on the furnace type, how complex the job is, and local labor rates. Knowing the main cost drivers helps you plan and compare accurate quotes from contractors. Other factors influencing cost include the need for ductwork modifications, the accessibility of the installation site, and any additional safety upgrades required by local codes.

What Is Included in a Furnace Installation Cost Estimate?

Estimates usually break down labor, materials, and permit or inspection fees. Labor depends on the hours and technician experience; materials include the furnace plus extras like venting or duct modifications. Ask for a line‑item estimate so you can see what’s covered. This transparency helps avoid unexpected expenses and allows you to make adjustments based on your budget.

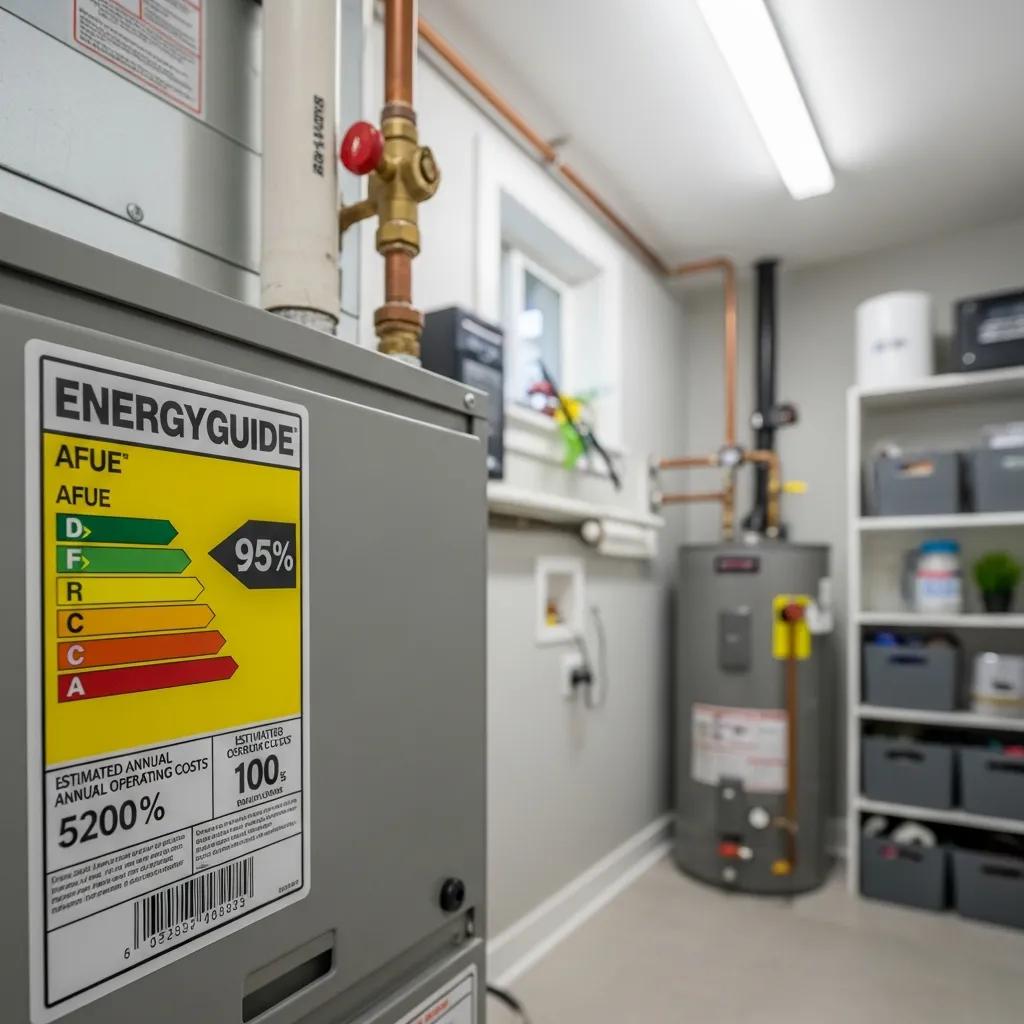

How Do Energy Efficient Furnace Setups Impact Installation Expenses?

High‑efficiency furnaces can cost more up front — sometimes due to specialized venting or controls — but they often save money on energy bills over time. Rebates and tax incentives may offset initial costs, making an efficient model a smart long‑term choice. Moreover, these systems often come with advanced features such as variable speed blowers and smart thermostats, which enhance comfort and further reduce energy consumption.

What Permits and Safety Requirements Must Be Met for Furnace Installation?

Before work begins, check the permit and code requirements in your area. Proper permitting ensures the installation is inspected and meets safety and building standards, which protects you and maintains compliance. Failure to obtain the necessary permits can result in fines, voided warranties, or difficulties when selling your home.

Which Local Codes and Permits Are Needed in Richmond and Surrounding Areas?

In Richmond, TX and nearby communities, common permits cover gas line work, electrical connections, and mechanical installations. Contact your local building department or let your licensed contractor handle permit filings so everything is done correctly. Staying informed about any recent code updates is also important to ensure your installation meets all current requirements.

How Does Compliance with Updated Safety Codes Ensure Installation Success?

Following the latest safety codes reduces risks like gas leaks, improper venting, or electrical hazards. Codes evolve as equipment and best practices change, so technicians who stay current deliver safer, more reliable installs. Compliance also helps protect your home insurance coverage and can improve the resale value of your property by demonstrating adherence to professional standards.

How to Choose the Right Furnace and Prepare for Installation?

Pick a furnace based on your home’s size, fuel type, and efficiency needs — and have a clear plan for the installation site. Preparing ahead saves time and avoids surprises on install day. Consider factors such as the furnace’s noise level, warranty terms, and compatibility with existing HVAC components to make the best choice for your household.

What Are the Benefits of Energy Efficient Furnace Types?

Energy‑efficient furnaces use less fuel to heat your home, which lowers monthly bills and reduces environmental impact. Many models qualify for rebates, and the improved efficiency can pay back the higher upfront cost over several years. Additionally, these furnaces often produce fewer emissions, contributing to cleaner indoor air and a healthier living environment.

What Should Be Included in a Furnace Installation Checklist?

A good checklist covers correct furnace sizing, proper ventilation and flue clearances, permit confirmation, and that all required materials and tools are on site. Review this list with your technician before work begins to avoid delays. It’s also wise to verify that safety devices such as carbon monoxide detectors are installed and functioning properly before and after the installation.

What Post-Installation Testing, Maintenance, and Emergency Repair Options Are Available?

After installation, a set of tests and a maintenance plan help keep the system running efficiently. For urgent problems, know when to call a licensed technician so small issues don’t become big failures. Regular maintenance visits can identify wear and tear early, extending the life of your furnace and maintaining optimal performance.

How to Perform Post-Installation Testing for Optimal Performance?

Post‑install checks should confirm proper airflow, temperature output, combustion safety, and that controls operate within the manufacturer’s specs. Technicians will adjust settings and document the results so you get predictable, efficient heat. They may also test safety shutoffs and verify that the system responds correctly to thermostat commands, ensuring reliable operation throughout the heating season.

When Should You Contact Licensed Technicians for Emergency Furnace Repairs?

Call for emergency service if you hear loud bangs, smell gas, experience a total loss of heat, or see signs of overheating. Quick action from a licensed pro protects your home and prevents additional damage. Never attempt to repair gas or electrical components yourself, as this can be dangerous and may void warranties or insurance coverage.

Why Choose Mega A/C Cooling and Heating for Your Furnace Installation Needs?

Mega A/C Cooling and Heating is a regional HVAC provider focused on reliable installs and straightforward service. We combine local knowledge with licensed technicians to give homeowners a safe, efficient result. Our commitment to customer satisfaction means we’re available for ongoing support and maintenance long after the installation is complete.

What Unique Value Propositions Do Our Licensed Technicians Offer?

Our team brings hands‑on experience with different furnace types, strict adherence to local codes, and a customer‑first approach. We aim to finish installs right the first time and stand behind our work. We also provide transparent pricing, detailed explanations, and personalized recommendations tailored to your home’s specific needs.

How to Schedule a Service Appointment for Furnace Installation in Richmond, TX?

Scheduling with Mega A/C Cooling and Heating is easy. Homeowners can contact us directly to discuss your needs and get a personalized quote. We’ll help you select the right unit and plan the installation for minimal disruption. Our flexible scheduling options and prompt response times ensure your project moves forward smoothly.

| Component | Description | Estimated Cost |

|---|---|---|

| Labor | Installation labor costs vary based on technician experience and time required | $500 – $1,500 |

| Materials | Includes the furnace unit and necessary components | $1,000 – $3,000 |

| Permits | Local permits required for installation | $100 – $300 |

This cost breakdown highlights the main components of a furnace install so you can compare estimates more easily. Keep in mind that additional costs may arise depending on your home’s specific requirements or unforeseen challenges during installation.

A furnace installation is an important investment that pays off when planned and executed properly. Follow the steps above, work with licensed professionals, and you’ll get safe, efficient heating that lasts. To learn more or schedule a consultation, reach out to Mega A/C Cooling and Heating — we’re here to help. Our team is dedicated to providing expert advice and quality workmanship to ensure your complete satisfaction.

Frequently Asked Questions

What are the signs that indicate a furnace needs repair?

Watch for loud or unusual noises (banging, rattling), uneven heating across rooms, strange odors (especially gas), and sudden increases in energy bills. If you notice any of these, call a licensed technician right away for an inspection. Early detection can prevent costly breakdowns and maintain your family’s safety.

How often should furnace maintenance be performed?

We recommend annual maintenance, ideally before the heating season. That visit typically includes filter changes, leak checks, heat exchanger inspection, and general tune‑up to keep your system efficient and reliable. Regular maintenance also helps identify minor issues before they escalate into major repairs.

What should homeowners do if their furnace stops working?

First check the thermostat settings and the circuit breaker. If those are fine and the furnace still won’t run, contact a licensed HVAC technician. Avoid DIY fixes on gas or electrical systems — safety comes first. Prompt professional service ensures a safe and effective resolution.

Are there any tax incentives for installing energy-efficient furnaces?

Many homeowners may qualify for federal or state tax credits, utility rebates, or local incentives for high‑efficiency equipment. Incentives change by location, so research programs in your area or ask your technician for guidance on eligible units. Taking advantage of these programs can significantly reduce your upfront costs.

What is the average lifespan of a furnace?

Furnaces typically last 15–30 years depending on type and maintenance. Gas units often last 15–20 years; electric units can reach 30 years with proper care. Regular maintenance helps extend service life. Upgrading to a newer, more efficient model may be advisable as your furnace approaches the end of its expected lifespan.

What factors should be considered when selecting a furnace?

Consider your home size, preferred fuel type (gas, electric, oil), efficiency ratings (AFUE), and budget. Proper sizing and correct installation matter more than brand alone — consult a licensed technician to find the best fit for your home. Additional considerations include noise levels, warranty coverage, and compatibility with smart home systems.

Conclusion

Proper furnace installation protects your safety, reduces energy waste, and keeps your home comfortable. By working with licensed professionals and following the steps above, you’ll get dependable performance and fewer surprises. If you’re ready to get started or have questions, contact Mega A/C Cooling and Heating for expert guidance and a smooth installation experience. Our commitment to quality and customer care ensures your heating system will serve you well for years to come.